Frequently Asked Questions - EKA DLP 3D Printers

EKA DLP 3D Printers are primarily used for jewelry manufacturing to create high-precision wax or castable resin patterns for lost-wax casting. They are ideal for producing fine jewelry designs with smooth surface finish and accurate detailing.

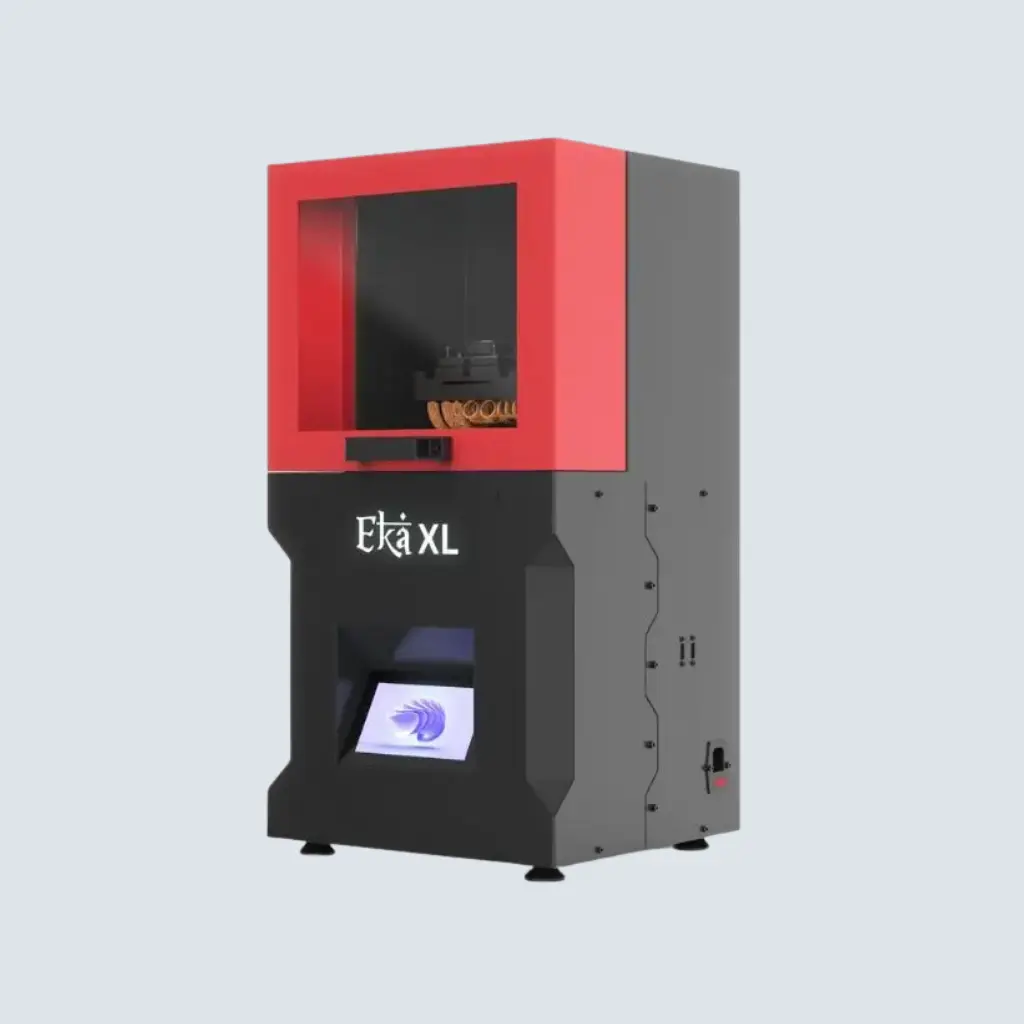

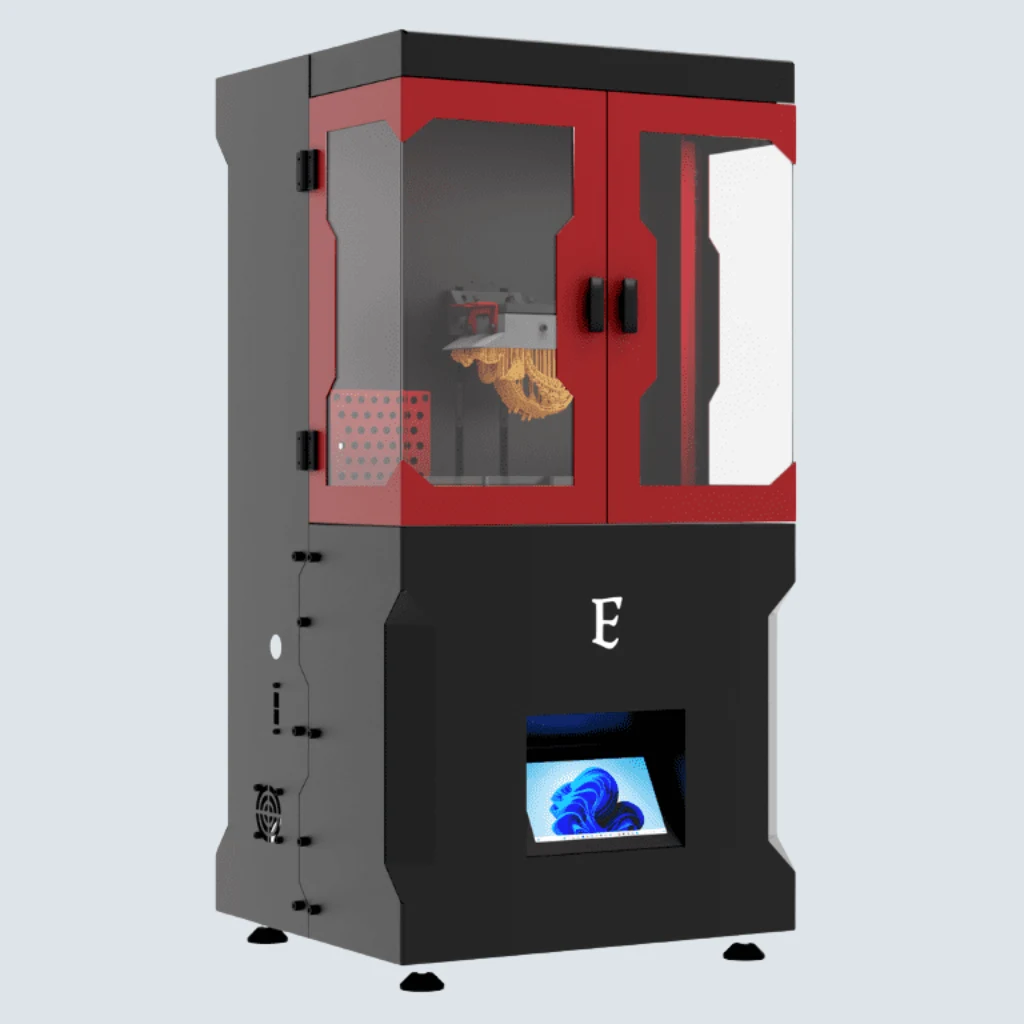

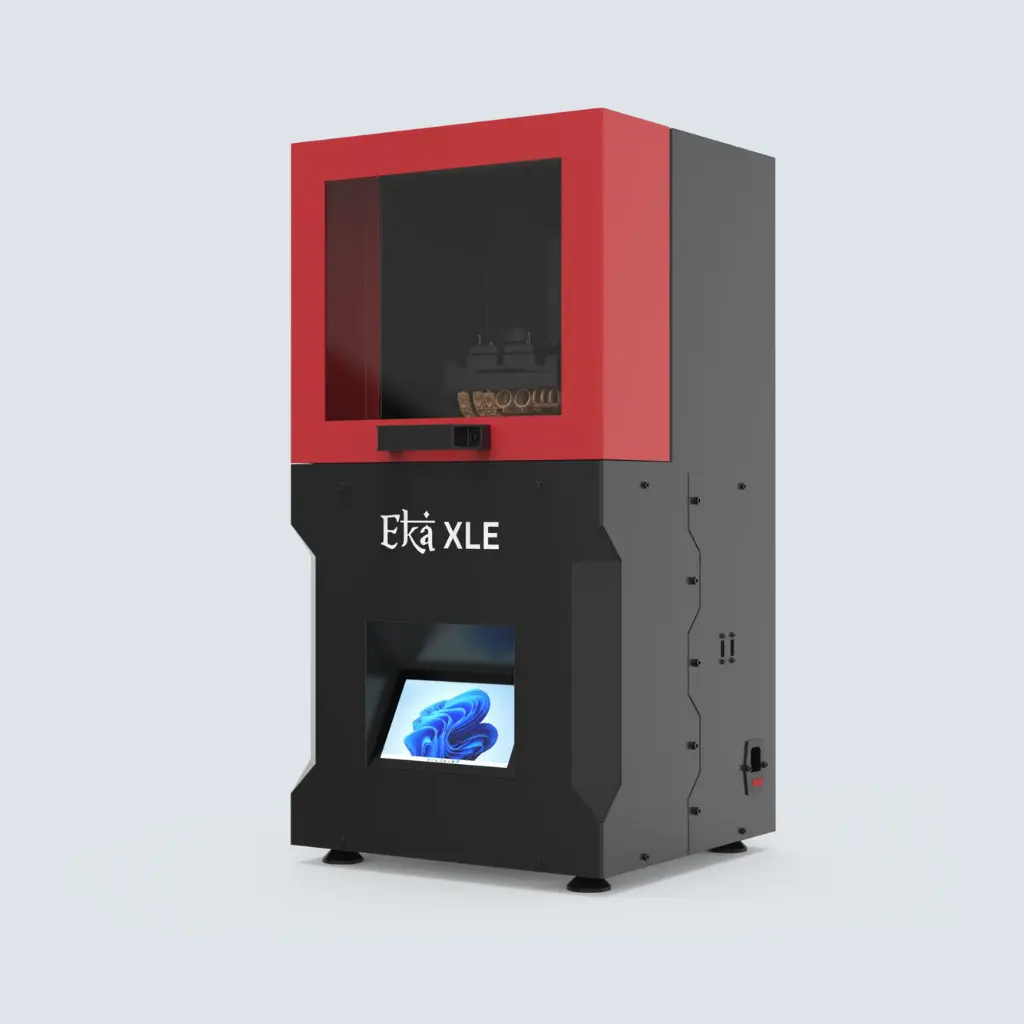

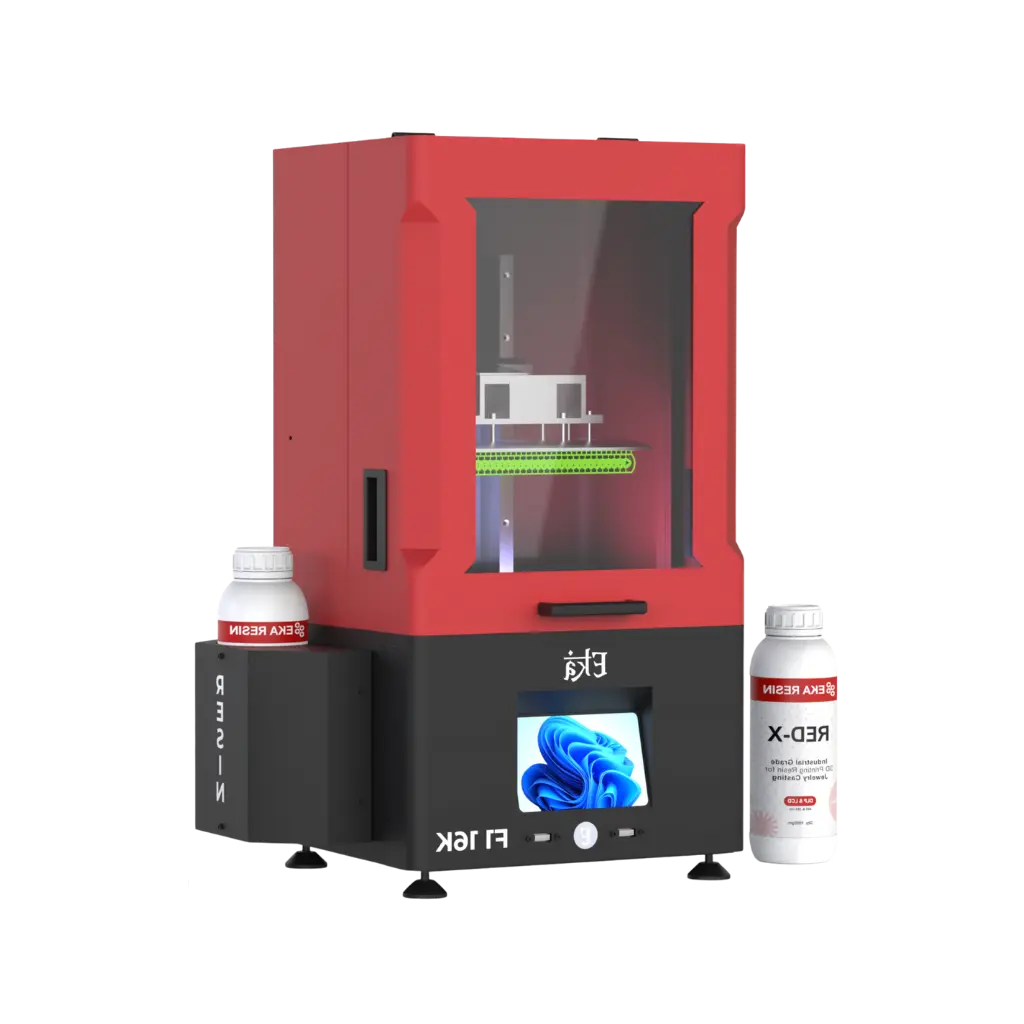

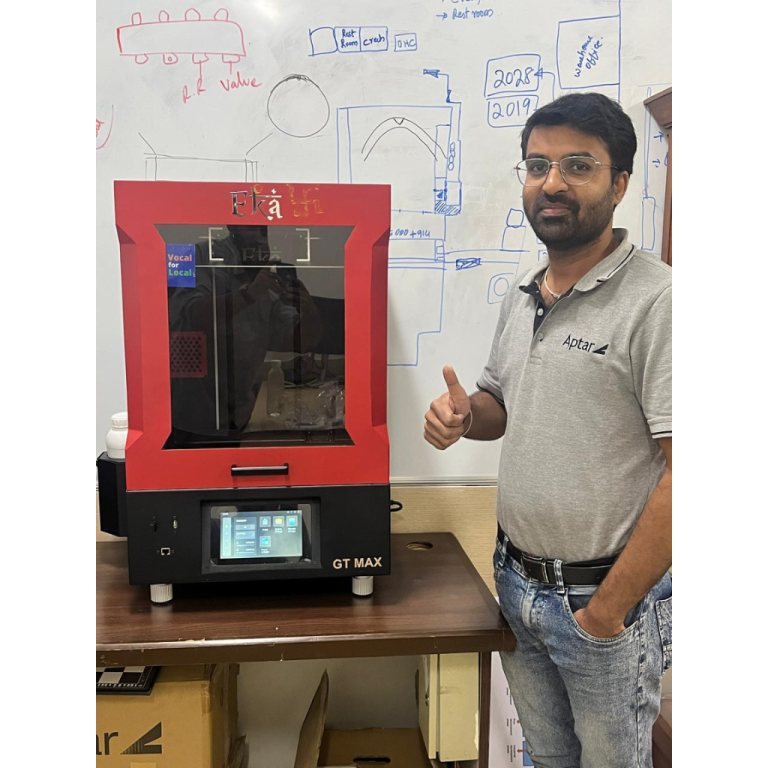

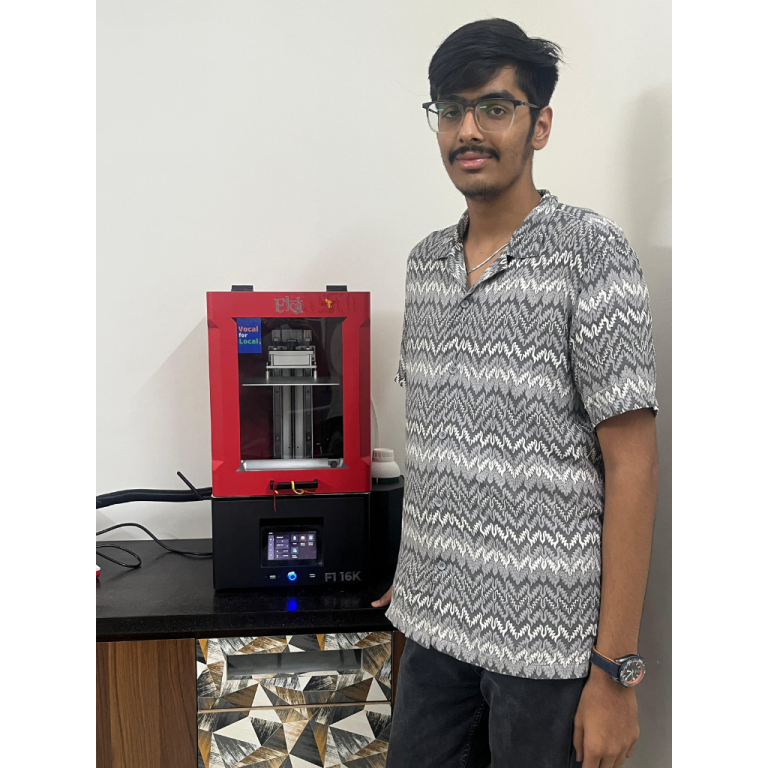

The best model depends on your production requirements. EKA XL is suitable for fine jewelry and small batches, EKA HT for high-speed production, EKA XLE for larger batch printing, and EKA F1 16K for ultra-high-resolution and premium jewelry designs.

Yes, EKA DLP 3D Printers are optimized to work with jewelry-grade castable wax and resin materials, ensuring clean burnout, minimal ash residue, and reliable casting results.

Yes, models like EKA HT and EKA XLE are designed for continuous operation and batch printing, making them ideal for jewelry manufacturers handling bulk orders and daily production workloads.

EKA DLP 3D Printers deliver ultra-fine detailing and high dimensional accuracy, making them suitable for intricate jewelry designs, micro pavé settings, and complex geometries.

Yes, EKA printers are designed with user-friendly interfaces and stable performance, making them suitable for both beginners and experienced jewelry professionals.