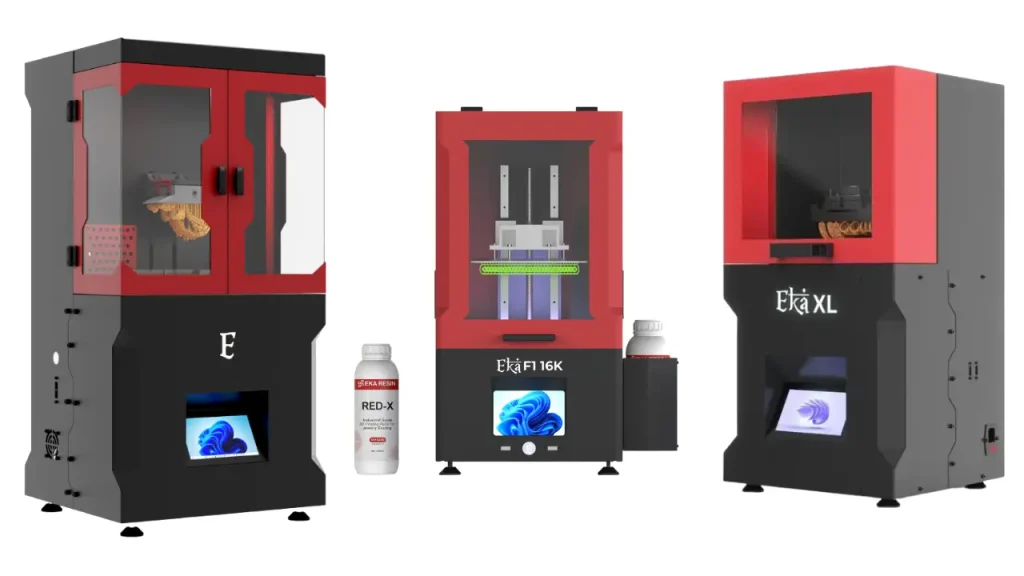

EKA Series of DLP 3D Printers for Jewellery

Are you from Jewelry Industry ? If yes then you are at right place to take your Jewelry making process to the next level.EKA series of DLP 3D Printers are Made in India High Speed DLP 3D Printers which helps you achieve your Jewelry Manufacturing Goals with maximum work efficiency !!!

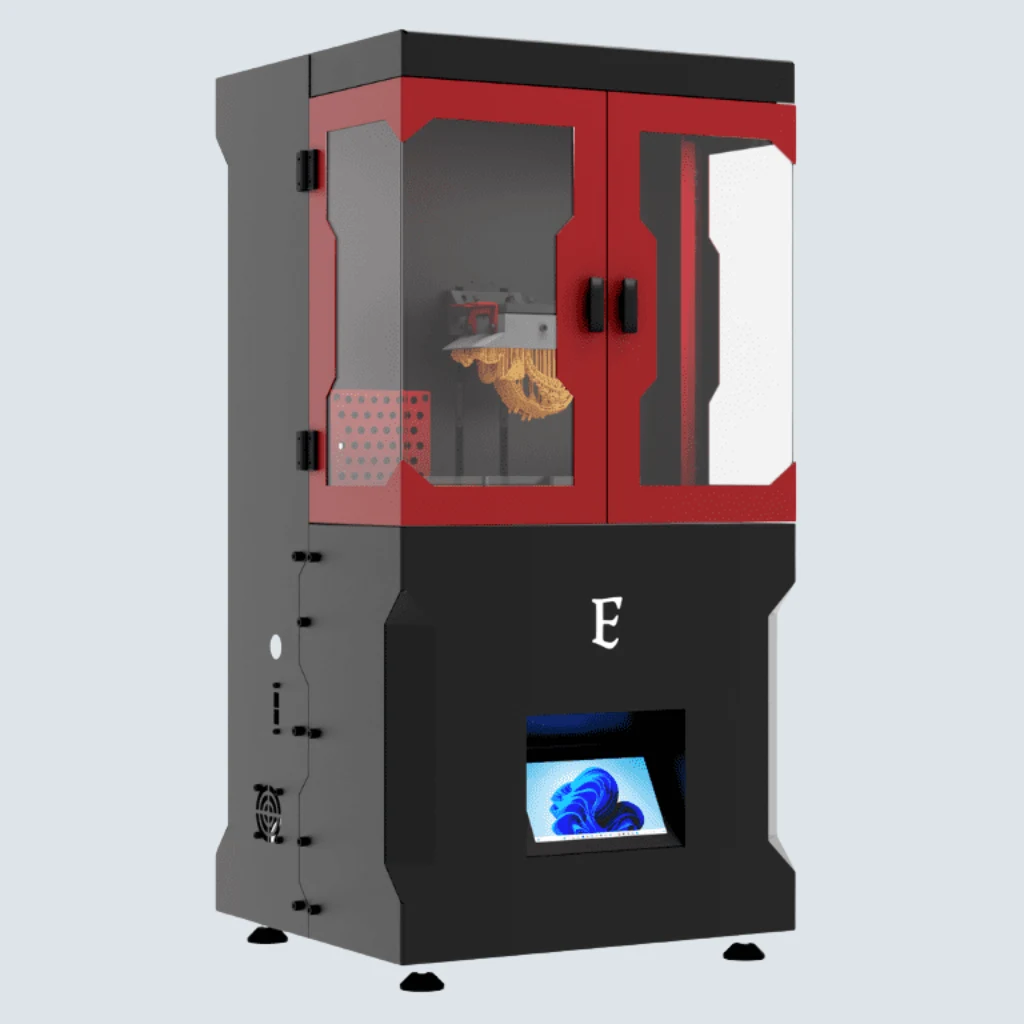

EKA HT (130x73x150 mm)

EKA HT is a high-precision DLP resin 3D printer specifically designed for jewelry manufacturers. It delivers sharp detailing, smooth surfaces, and excellent casting-ready patterns for complex jewelry designs.

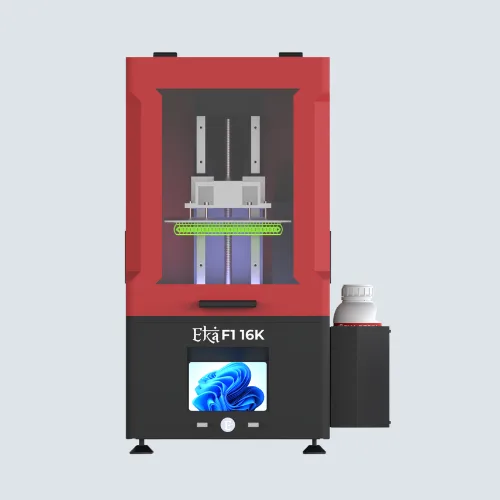

EKA F1 (212×118×240 mm)

EKA F1 16K is a next-generation jewelry-focused LCD 3D printer featuring 16K ultra-high resolution for exceptional detailing and surface quality. Designed specifically for jewelry masters, micro-details, and intricate designs.

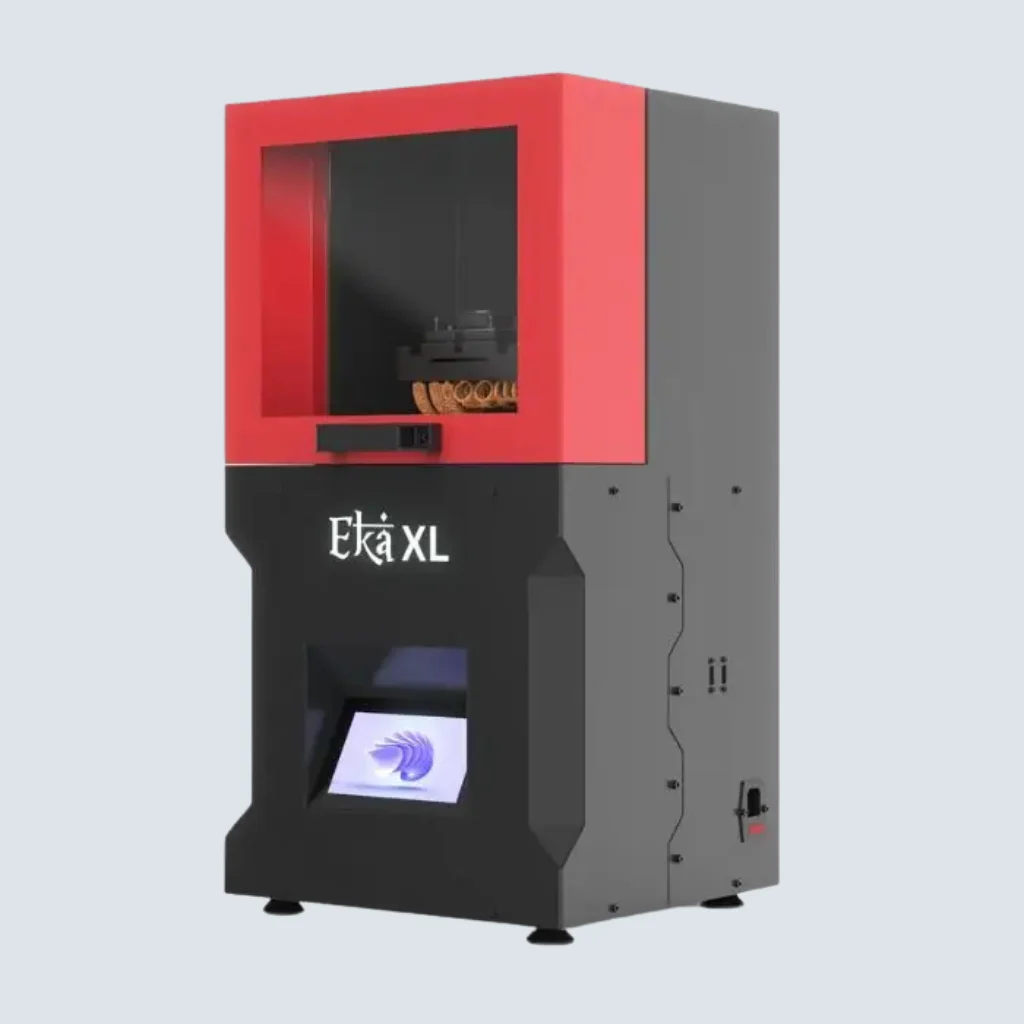

EKA XL (125x70x140 mm)

EKA XL is a compact and reliable jewelry DLP printer ideal for daily production. It offers consistent accuracy and smooth finishes, making it perfect for small to medium jewelry workshops.

Why use EKA Series of DLP 3D Printers for Jewelry Making? (Watch Video)

6 Step Jewelry Making Process with EKA

1. CAD Design

Prepare a Jewelry CAD Design with CAD Software.

2. STL File

Convert CAD Design into .STL file format to use with EKA Controller Software.

3. Prepare a Program

Take .STL file into EKA Controller software and prepare a program to start a 3D Print with EKA.

4. 3D Print with EKA

Apply program from EKA controller to EKA and start a 3D Print of CAD Design, You have CAM Piece Ready with you.

5. CAM Finishing

Now you have CAM Piece of your CAD design, Do a proper finish with tools and use it for Silicone Mold / Direct Casting Process.

6. Jewelry in Hand

Do High Temperature Jewelry Casting from CAM Piece, and Your CAD design is Ready as a final Jewelry.

What Jewelry Professionals Say

About EKA DLP 3D Printers.

We have been using the EKA DLP 3D Printer for wax pattern printing, and the surface finish and accuracy are excellent. It has significantly reduced our casting rework and improved overall productivity.

EKA printers deliver consistent results even for intricate jewelry designs. The machine stability and print quality are perfect for daily production use.

We compared multiple DLP printers before choosing EKA. The detailing, print speed, and after-sales support made it the right decision for our workshop.

EKA DLP 3D Printer helped us achieve smoother wax patterns with minimal post-processing. Our production efficiency has improved noticeably.

The printer is reliable, easy to operate, and delivers sharp details every time. EKA’s technical support team is very responsive and helpful.

We use EKA DLP printers for high-detail jewelry masters. The dimensional accuracy and repeatability are impressive, even for complex designs.

After installing the EKA 3D Printer, our rejection rate during casting has dropped significantly. It is a dependable solution for professional jewelers.

Excellent machine for jewelry wax printing. The print clarity and consistency help us maintain high-quality standards for premium jewelry.

EKA DLP 3D Printer offers great value for money. The performance is comparable to international brands at a much better cost.

Reliable performance, minimal maintenance, and excellent print results make EKA an ideal choice for jewelry professionals.

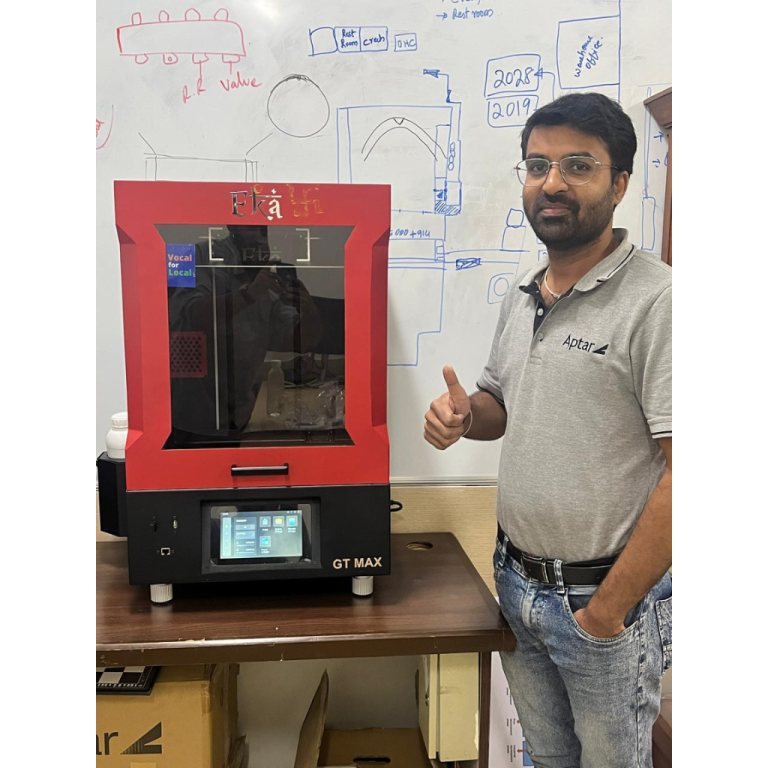

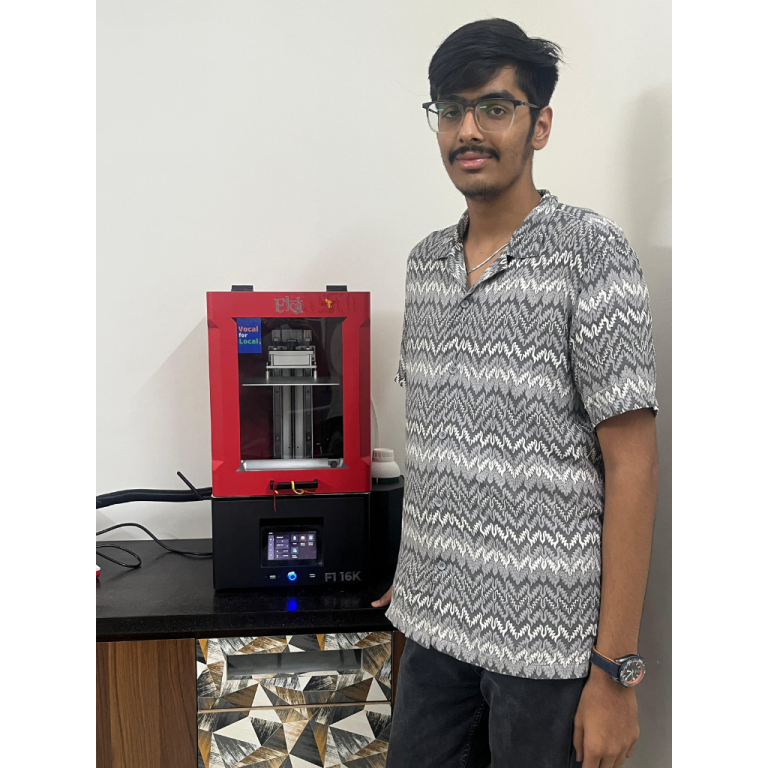

Our Latest Jewelry 3D Printer Installations

Delivering high-precision DLP 3D printers to jewelry manufacturers, casting houses,

CAD/CAM studios, and production units across India.

1. Latest Jewelry Printer Installations

Explore our recent EKA DLP 3D printer installations at jewelry manufacturing units, casting houses, and CAD/CAM jewelry studios across India.

2. Pan-India Technical & Service Support

With fast remote assistance and on-site support, EKA ensures smooth and uninterrupted jewelry production for our customers nationwide.

3. Trusted by Professional Jewelers

From small jewelry workshops to large-scale manufacturers, EKA DLP 3D printers are trusted for consistent accuracy, smooth wax patterns, and reliable performance.

Check Our Latest Interview

FAQ

Yes, EKA is based on DLP(Digital Light Process) Technology, Compare to LCD based 3D Printer, EKA is Superior in every aspect of quality and performance due to it’s advanced DLP Technology.

Yes, EKA is Indigenous 3D Printer.

Yes, We will Provide Full Onsite Training to our customer with Lifetime after sales support.

EKA supports both Direct Castable & Non-Castabe Resin Material.

EKA Comes with standard 24 Months of Warranty, We will cover full warranty during this 24 Months.

Yes, EKA is made for Production work only, High Speed CAM work is best advantage of EKA.