The Indian jewelry industry has always been known for its craftsmanship, intricate designs, and precision. However, as customer demand increases and designs become more complex, traditional jewelry manufacturing methods are no longer sufficient to meet modern production needs. This is where DLP 3D printing technology is transforming the jewelry manufacturing landscape across India.

Today, DLP 3D printers for jewelry are helping manufacturers achieve unmatched accuracy, faster production cycles, and superior surface finish making them an essential tool for modern jewelry businesses.

What Is a DLP 3D Printer?

DLP (Digital Light Processing) 3D printing is an advanced resin-based printing technology that uses a digital projector to cure an entire layer of resin at once. Unlike conventional methods, DLP printing delivers:

Extremely fine details

Smooth surface finish

High dimensional accuracy

Faster printing speeds

For jewelry production where micron-level precision matters DLP technology is far superior to many traditional manufacturing techniques.

Why the Jewelry Industry in India Is Adopting DLP 3D Printing

India is one of the world’s largest jewelry manufacturing hubs, with cities like Surat, Mumbai, Jaipur, and Rajkot leading the industry. As competition grows, jewelry manufacturers are adopting DLP 3D printers to stay ahead.

Key reasons for rapid adoption include

Rising demand for intricate and customized designs

Need for faster turnaround times

Reduction in manual labor and errors

Consistent quality for large-scale production

Faster Production and Shorter Lead Times

Traditional wax carving and mold-making processes are time-consuming and heavily dependent on skilled labor. DLP 3D printers dramatically reduce production time by:

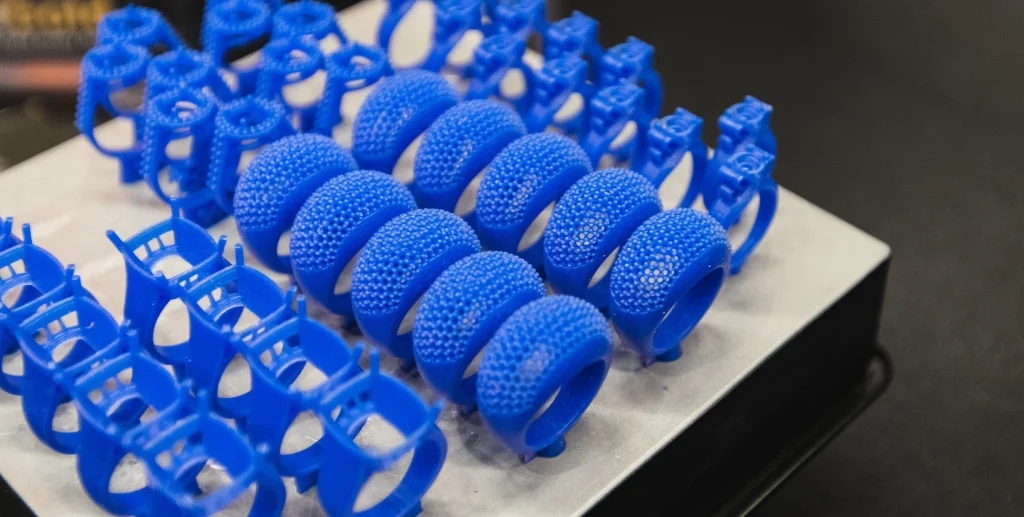

Printing multiple designs in a single build

Eliminating manual carving

Enabling rapid prototyping and sampling

For jewelry manufacturers handling bulk orders or export timelines, this speed advantage is critical.

Design Freedom and Customization

Modern customers demand custom jewelry, personalized designs, and complex geometries that are difficult to achieve manually.

With DLP 3D printing:

Designers can create highly complex lattice and micro-detail designs

CAD files can be modified instantly

Custom orders can be produced without extra tooling costs

This opens new revenue opportunities for jewelers and designers alike.

Role of Indian-Made DLP 3D Printers

With the rise of Indian-manufactured DLP 3D printers, jewelry businesses now have access to advanced technology at competitive pricing, along with faster service and localized support.

Indian brands like EKA DLP 3D Printer focus specifically on the needs of the jewelry industry offering machines optimized for wax printing, high resolution, and continuous production environments.

The Future of Jewelry Manufacturing in India

As technology continues to evolve, DLP 3D printing will become a standard part of jewelry production. Businesses that adopt this technology early will benefit from:

Faster innovation cycles

Higher product quality

Better customer satisfaction

Stronger competitive advantage

DLP 3D printers are not just tools they are shaping the future of jewelry manufacturing in India.

The adoption of DLP 3D printers for jewelry production in India is transforming the way jewelry is designed, prototyped, and manufactured. From superior wax patterns and faster production to cost savings and design freedom, DLP technology is redefining industry standards.

For jewelry manufacturers looking to scale, innovate, and maintain precision, investing in a high-quality DLP 3D printer is no longer optional it’s essential.